As a leader in dental technology and digital convergence, Aurora DTC’s open architecture and multiple platforms allows your laboratory to use our outsourcing services regardless of the technology you employ. Whether you need us to scan impressions, design and mill restorations or merely outsource production when your mill runs at capacity, Aurora DTC’s technology is as flexible as you need it to be.

MILLS

HAAS DT-1

Haas’ DT-1 is a compact, high-speed drill and tap machine with full milling capabilities. Its incredible tool changing speed swaps tools in just 0.8 seconds, while retaining smooth, quiet operation and extreme thermal stability. With a 15” color LCD monitor and 1 GB of program memory, we’re able to reduce turnaround times through streamlining our workflow.

HAAS VF-2TR

With muscle that greatly surpasses tabletop mills, the Haas VF-2TR is perfect to fabricate titanium overdenture bars and abutments. Five-axis milling capacity combines with a two-axis trunnion to offer the most consistently accurate fabrications from your designs or ours.

DMG ULTRASONIC 20

Combining state-of-the-art five-axis milling with sonic technology, the DMG Ultrasonic fabricates restorations as precisely as you design them. Highly calibrated machining allows for consistent surface quality and impeccably precise margins, allowing CMC to offer a multitude of cost-efficient restorations to our laboratory partners.

ROLAND DWX-50

Roland’s five-axis workhorse was developed specifically for milling dental restorations, making it an ideal solution for milling zirconia and other ceramic restorations. Its open architecture allows it to be fully compatible with most laboratories’ existing technology, enabling CMC to integrate into your workflow without hassle.

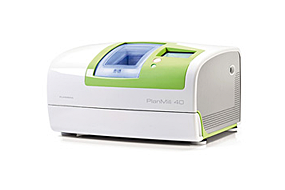

PLANMECA® PLANMILL 40™

Designed to operate in conjunction with the 3M™ True Definition Scanner, the Planmeca® PlanMill 40™ offers the capability for CMC to design and mill restorations inside the 3M environment, crafting perfect marginal ridges and central grooves.

ROLAND DWX-52DCI

True 5 axis milling (3+2 axis or simultaneous 5 axis) 6 position Automatic Disc Changer w/ integrated barcode verification scanner Quiet, reliable, user-replaceable 30,000 RPM spindle with 4mm collet Integrated ionized air system prevents particle buildup when milling PMMA 15 position automatic tool changer with built-in tool length/breakage sensor Compatible materials: zirconia, wax, PMMA, composite resin, PEEK, gypsum, glass fiber reinforced resin. V-Panel control for easy operation, maintenance and service Powerful DWIndex software for mill production analytics & reporting

CEREC® MILLING AND GRINDING UNIT

The CEREC® milling and grinding unit and CEREC software are optimally synchronized with one another. Grinding or milling your restoration design is extremely precise, giving the restorations smooth surfaces. Even very fine fissures are precisely prepared and the edges are very even.